Brochure Digestate Dewatering by Evaporation Ver 8

Biogas digestate is a valuable resource but has high economic handling costs and poses potential environmental difficulties, especially for farmers in Nitrate Vulnerable Zones (NVZ). If not carefully managed, the nitrates and phosphates embodied within these products are a potential hazard to the land and water resources. Further, digestate and slurries emit some methane gas, a powerful greenhouse gas and ammonia vapour which is detrimental to the wider air quality.

Digestate also contains other valuable nutrients and biomass. Capturing and returning all of the nutrients and biomass to the land is essential for long term soil health and helps with increasing the carbon storage in the land. Concentrating these products by ‘squeezing’ out the water, the economic handling and management costs for farmers is greatly reduced meaning fewer tractor miles driven, smaller storage requirements and the production of a much higher value product if transporting the ‘fertiliser’ to arable farmers in other regions.

Dynameau have two processes available. If heat is available from a CHP, then the evaporation technology can be used. If there is no heat or insufficient heat available for the volumes requiring processing, then the membrane system can be used.

Evaporation Technology

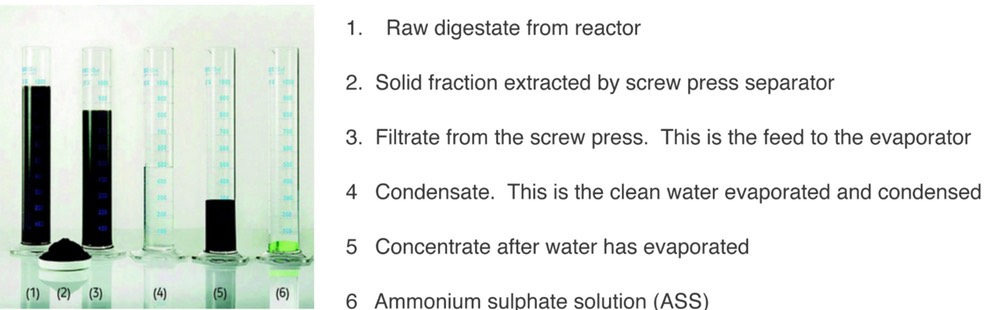

The digestate extracted from the AD biogas plant is evaporated using the waste heat from the electrical generation CHP. The digestate is reduced in volume by around 75%. Four products are delivered:

1. Ammonium Sulphate liquid fertiliser.

2. Thickened digestate for storage, spreading or drying and pelletising.

3. Clean water for discharge at any time.

4. De-watered and stackable solids from the raw digestate.

Biogas AD digestate is drawn from the reactor tank and taken directly to the separator. Here the solids in the digestate, typically around 10%, are squeezed out under high pressure using a screw press. The solids fall to the ground and are stored for land spreading when required. The press-water retains around 3% - 4% solids and is passed to the first of two low pressure evaporation vessels inside the treatment building. Here, heat from the CHP generator is used to raise the temperature in the evaporation vessels.

The steam driven off is rich in ammonia vapour and this is reacted with sulphuric acid in a scrubber to produce a valuable stream of Ammonium Sulphate liquid fertiliser. Both the evaporation vessels have these scrubbers to maximise the recovery of this valuable fertiliser.

Steam from the process is condensed and polished with a biologically step to convert any residual ammonium to nitrate before being discharged to the land or a stream. Since this is clean water, it will be (subject to EA approval) allowed to be discharged at any time.

The evaporation vessels reduce the digestate by approximately 75% by volume. The thickened digestate is discharged as a cool, solids rich liquid for storage until needed for land spreading. This thickened digestate retains all the valuable nutrients except the Ammonia and the biomass in the press water.

Typical evaporation capacity is up to 2.5 litres per kW thermal delivered to the evaporation heat exchangers within the low pressure vessels. A typical 500kW CHP will produce 500kW of thermal energy. This is sufficient to process 30 tonnes per day of press water from the screw press which is equivalent to 35 tonnes per day of raw digestate. Larger quantities of digestate require additional evaporators and additional heat pro rata.

Please contact us to visit a digestate processing plant located in Northern Ireland working in conjunction with a farm AD plant and a 500 kW CHP

Back to the Digestate & Slurry Dewatering Page