Oily Water Separator Brochure Ver 5

Overview

High performance, tilted plate, single and double stage oily water separators.

Pre fabricated welded mild steel, package plants.

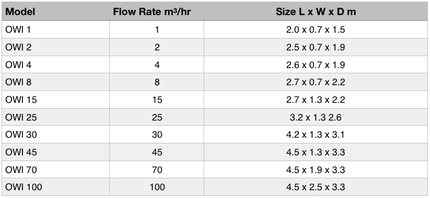

Capacities: 2 - 100 m3 per hour

Performance

Stand alone systems to achieve 15 - 30 mg/l oil in water based on an oil removal performance of 50 micron oil droplets of SG 0.86 in water with an SG of 1.0

If emulsified oily water requires treatment, then Electrocoagulation (EC) is needed to break the emulsion. The Oily Water Separator should be used as a pre-treatment to the EC to achieve < 5 mg/l oil in water

Description

An oily water separator - or interceptor - is used for the separation of “free", floating oil and water. Many industries make oily waste water such as heavy industry, docks, docks, oil and gas sector, truck and locomotive wash stations, power stations and airports.

Oily water separators do not remove “emulsified" oils from water. These will pass through an oily water separator. To separate and remove emulsified oils an second process is needed and the ideal process is Electro Coagulation. See Electrocoagulation on this web site.

Rain fall becomes surface water run-off from hard standings and will often contain oil and this run-off water needs to be cleaned before discharge to the environment.

Not only heavy industry but food processing sectors also make dirty, oily waters, especially abattoirs and ready-meal and processed food makers.

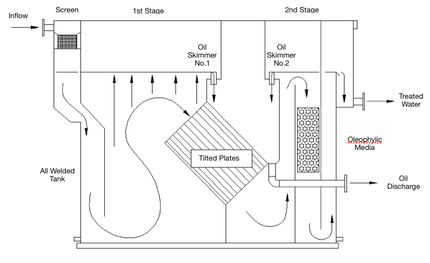

The oily water separator uses enhanced gravitational separation via tilted plates and second stage oleophilic coalescing filters for polishing. Expected oil removal rates are 99.9% of 50 micron oil droplets of an SG of 0.86 in water of an SG of 1.0.

The oily water separators are stand-alone package plants incorporating adjustable oil skimmers in the first and second stages plus an oil collection tank. The second stage employs an oelyophilip, coalescing step for enhanced removal of fine oil droplets.

Optional additions to the process are automatic pre screening, feed pumps, heated oil collection tank to prevent thickening of oils and aeration of the second stage coalescing filter for enhanced performance.

Typically the oily water separators are flat bottomed but in the case of heavy solids entrained in the oily waste water, hopper bottom versions are available.